4 Flush Joint Casing

VAM® Connection Selection Guide. VAM ® has been the leading brand of premium connections in the oil and gas industry for over 50 years. Each year VAM ® designs new connections, extends product lines and qualifies new sizes to the most stringent specifications to meet our customer needs. 4.5' SDR 17 PVC Flush Thread Well Screens and Casings Larger Image All PVC well screens and casings used on this project shall be manufactured by Atlantic Screen and Manufacturing, Inc. And conform to ASTM F-480: 'Standard Specification for Thermoplastic Well Casing Pipe and Couplings Made in Standard Dimension Ratios (SDR), SCH 40 and SCH 80.'

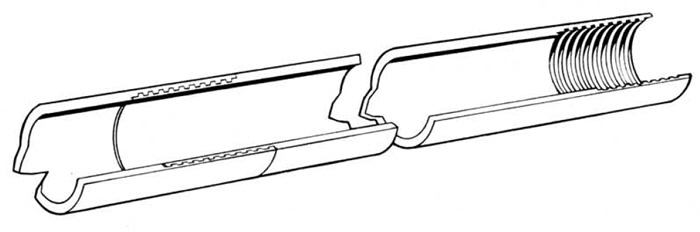

','after_title':'</h2>','pager':false,'paged':1,'template':'single.tmpl','item_class':'services-single-item','container':false,'custom_class':'services-page-single'}'>Tight clearance downhole requires a connection strong enough to do the job without a coupling. Inter-Mountain Pipe Co. has sixteen years of experience in helping our customers solve a variety of such problems in some very hostile downhole environments. Whatever thread you choose, we’ll make the necessary crossovers and lift subs and we will provide it in the lengths you need.

4 Flush Joint Casing Specs

Inter-Mountain Tapered Flush (IMTF) was designed so that the torque required to make the connection would resist back-off during core drilling. Inter-Mountain Speed Casing (IMSC) features less taper (and thus less torque). As the name implies, fewer threads per inch allow faster make-up. Also, Diamond Core Drill Manufacturers Association (DCDMA) “W” series threads are available.

Other customer-driven original designs include Inter-Mountain Modified Sonic (IMMS), a coarse drill pipe thread form which has been used for dry coring as well as casing, and Inter-Mountain Rope Thread (IMRT), developed for use with casing driver/advance systems and usually ordered in a left-hand version. Both provide greater load-bearing surface area and are particularly suited to heavy wall alloy steels and the applications which call for their strength.

4 Flush Joint Casing Joint

VAM® FJLTM (Flush Joint Liner) is a 100% inside and outside flush integral connection providing maximum clearance with optimum strength for liners, moderate depth casing, and tight-hole tubing strings.

- Available in sizes from 2 3 /8″ to 11 7/8″

- Yield strengths from 80 ksi to 140 ksi

- Standard, alternative and special drifts

- Carbon, Martensitic stainless steel (13%Cr & Super 13%Cr) and Nickel base Alloys.

- Drilling, production and contingency liners

- Moderate depth production casing /slim hole designs

- Tiebacks in medium sizes

- Tight hole tubing strings in small sizes.

- Integral Flush Design. The O.D. and I.D. are 100% flush (there is no upset). The I.D. is bored and recess-free for smooth, efficient flow. The O.D. is turned to tight tolerances.

- Multiple Seal System. This multiple seal arrangement ensures gas-tight sealing integrity to 100% of the rated burst and collapse of the pipe body.

- Interference Tapered Thread. Thread load flank has a 15° reverse angle to resist jump out. Thread stabbing flank has a 45° angle for fast, trouble-free make-up.

- In order to provide optimum strength, the VAM® FJL™ is designed for 65% to 70% efficiency under tension in medium wall thickness.

- The design of VAM® FJL™ exhibits an exceptional bending resistance for a connection of this class.

- Excellent gas tightness.

- Maximum clearance (100% flush)

- Easy to use and repair

- Only slight pin end swaging is needed for machining threads.